How to Start a Metal Parts Manufacturing Business Efficiently

You may already know that the metal parts manufacturing industry can generate an average of $2.8 trillion in 2023, according to WQAD80. That’s a testament to the immense demand for precision metal fabrication in industries like construction and marketing today.

If you’ve been contemplating launching a metal fabrication startup, now is the perfect time. But turning ambition into a thriving business requires:

- A strategic plan

- The right tools

- A deep understanding of the fabrication industry

Metal Parts Production and Industry Overview

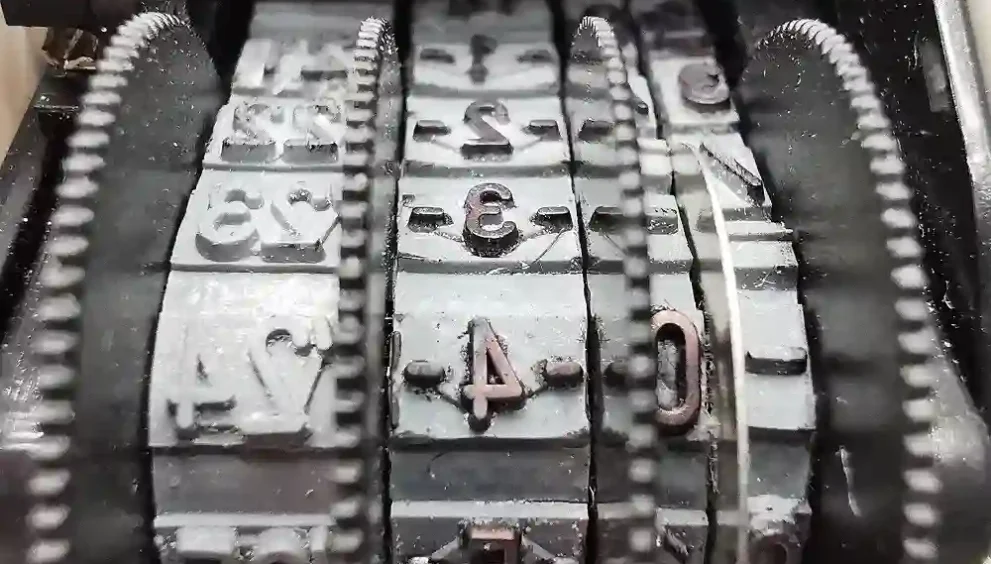

Almost everything around us, from the bolts that hold bridges together to the intricate components inside your phone, owes its existence to the world of metal parts manufacturing. Without it, the construction of cities and even the marketing of products would stall. The process isn’t as straightforward as it might seem. Producing metal parts requires precision, patience, and — most importantly — a clear understanding of what your customers need. That attention to detail is why metal parts manufacturers often become trusted partners in construction and industrial supply chains.Steps to Create a Manufacturing Business Plan

When you start a metal parts manufacturing business, you should never rush into production with a “figure it out as we go” mentality. Map a path that takes you from day one to long-term success. That journey begins with setting the right goals. Are you focused on high-volume production for large industries, or do you prefer smaller-scale projects that allow for more customization? Each path comes with its opportunities and challenges, and defining your direction will help you make smarter decisions when it comes to:- Equipment

- Staffing

- Marketing

- It’s attending trade shows

- Building a strong online presence

- Investing in advanced machinery that can produce faster and more precisely than your competitors

Budgeting and Investments in Metal Parts Production

Money talks in any business, but in metal fabrication, it shouts. Equipment alone can eat up a significant chunk of your startup budget, especially if you’re aiming for top-tier tools like CNC machines or advanced welding setups. But cutting corners on equipment can cost you more in the long run, whether it’s through:- Delays

- Subpar quality

- Unhappy customers

Building a Metal Parts Manufacturing Facility

Stepping into the world of metal fabrication is exhilarating, but setting up your facility requires more than just a checklist. It’s a commitment to quality and efficiency. The right tools are non-negotiable. Start with the basics:- Welding machines

- Cutting tools

- Bending equipment

- Materials

- Clear pathways for transport

- Dedicated zones for important tasks

Hiring Professionals to Enhance Manufacturing Efficiency

Even with the best equipment, it’s people who turn raw materials into masterpieces. In metal parts manufacturing, expertise is everything. A skilled welder knows the difference between a weld that holds and one that endures. A seasoned machine operator understands how to push equipment to its limits without risking quality or safety. When hiring, prioritize both experience and adaptability. Technology in fabrication evolves quickly, and the best professionals are those eager to learn and grow. Don’t shy away from investing in training programs either — sometimes the perfect employee is someone you’ve helped shape into the role. Building a strong team also means fostering a culture of collaboration. Encourage open communication between roles, from engineers to floor operators. After all, a cohesive team creates a more resilient business.Fabrication Industry Insights and Trends

Metal parts manufacturing is evolving faster than ever, and the savviest entrepreneurs are tapping into advancements reshaping the industry. Take hybrid manufacturing, for instance — a combination of traditional methods like CNC machining with cutting-edge technologies such as additive manufacturing. Companies are now using 3D metal printing not just for prototyping but for creating fully functional, load-bearing components. For example, aerospace firms use metal printing to produce intricate engine parts that are lighter yet stronger than conventionally made counterparts. As a startup, understanding which technologies align with your niche can help you scale smarter. Automation is revolutionizing how fabrication happens. Instead of fully automated factories, many smaller businesses are adopting collaborative robots — or “cobots” — to handle tasks like repetitive welding or assembly. These cobots are cost-effective for startups because they don’t require a complete overhaul of production lines. Imagine having a robotic arm that welds components while your team focuses on refining designs or troubleshooting client issues — it’s efficiency without sacrificing flexibility. Then there’s the sustainability angle, and it’s more than a PR move. Closed-loop manufacturing, where scrap metal is recycled back into production, is gaining traction. Companies using this model decrease the use of raw materials by 50%, according to Deksera. As steel suppliers pivot toward green steel — produced with minimal carbon emissions — fabricators who adapt early will be better positioned to negotiate favorable contracts and meet increasingly stringent regulations.Solutions to Common Challenges in Metal Fabrication

Running a metal parts manufacturing business is rarely smooth sailing, but specific strategies can turn obstacles into opportunities. One pressing challenge many startups face is skill shortages. Skilled machinists and welders are in high demand, and hiring them can strain a fledgling budget. Consider upskilling your team instead of hiring exclusively seasoned professionals. For example, apprentice programs or partnerships with local trade schools can create a steady talent pipeline. Material costs are another hurdle, especially when prices fluctuate due to global events or supply chain issues. Diversification is a smart strategy. Source from multiple suppliers across regions to mitigate risk. Some manufacturers are also exploring alternative metals, like aluminum alloys or composites, which can offer similar strength with less weight and cost. Quality control often becomes a bottleneck when scaling production, but tech can help. AI-powered inspection systems now identify defects in real time, preventing costly recalls or rework. Finally, staying compliant with regulations can be daunting, especially as laws tighten around environmental impact and workplace safety. Don’t view compliance as a hurdle — it’s an opportunity to stand out. Companies that exceed standards often use certifications like ISO 9001 as a selling point. Going beyond what’s required signals reliability to potential clients and partners, giving you a competitive edge.Business Growth Strategies to Drive Succes

Marketing in metal fabrication might sound like a simple “word-of-mouth” game, but in today’s competitive landscape, it’s anything but. To truly stand out, your approach needs to combine the traditional with the cutting-edge. Let’s start with what works: relationships.- Contractors

- Industrial designers

- Project managers

- Attend trade shows

- Sponsor local industry events

- Host workshops at your facility to showcase what you can do

Build Your Vision with Precision and Efficiency

Launching a metal parts manufacturing business is no small feat, but with the right strategies, tools, and partnerships, you can turn your vision into a thriving enterprise. Start by exploring our expert resources crafted to help startups like yours achieve unmatched precision and efficiency in metal fabrication.Read More latest Posts

- 11 Future Trends in Laser Face Lift Technology and Techniques

- Top 4 Must-Have Auto Travel Accessories for Outdoor Enthusiasts

- How to Start a Metal Parts Manufacturing Business Efficiently

- An Ultimate Guide to Choosing Cars for the Perfect Road Trip Adventure

- Benefits of Owning a Sport Compact Car: Why They’re a Great Investment